“The engine and propeller are there to keep the pilot cooled.

If it quits you will quickly watch the pilot start sweating.” -Unknown

Learning how your engine works will make you a better pilot. No argument against it, system knowledge is key.

Most pilots, will tell you that the aircraft engine is briefly covered in flight training. Even though there are a few questions about the engine during the oral exam, pilots don’t have a good understanding of how or why aircraft engines work in such a way. Let’s take a closer look at what makes up an airplane engine and its most common parts, which is vital whether you’re getting a pilot license or looking to expand your knowledge of aviation.

Cylinders

Spark Plugs

Magnetos

Lubrication

Vacuum Pump

Alternator

Starter

Carburetor

Cylinders

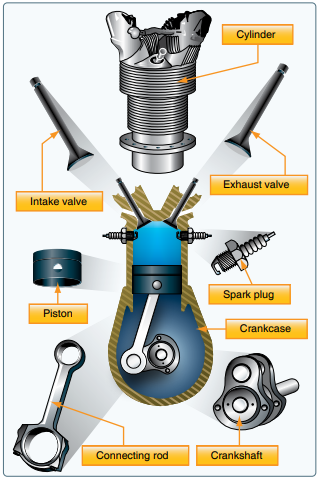

Most training aircraft at top pilot aviation academies have 4-cylinder Lycoming or Continental Engines. The Cylinders are basically housing the pistons. Those pistons are all connected to each other via the crankshaft. Each cylinder has one piston and two spark plugs. They each have an intake valve and an exhaust valve. The intake valve is what feeds the cylinder with air and fuel when it opens. The exhaust valve is connected to the aircraft exhaust, and it is where the burnt gases exit the cylinder. This process happens for every other revolution, meaning at 2,700 RPM, the four cylinders go through an emission cycle 1,350 times! This knowledge is crucial whether you're attending Part 61 or Part 141 flight schools.

Spark Plugs

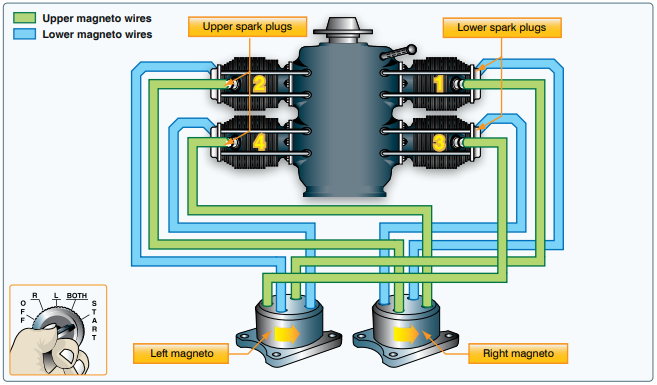

Like we mentioned, each cylinder has two spark plugs for redundancy and better performance. In our Diamond and Cessna aircraft, there are a total of 8 spark plugs.

Magnetos

Magnetos supply the power needed to cause a spark in the spark plugs. We have two magnetos per engine. Each magneto feeds one spark plug per engine so that in the event of a magneto failure, the remaining magneto can continue to provide the spark needed to keep the engine running. The magneto is engine-driven, meaning once the engine starts, it will continue to run until it quits. A total loss of electrical power has no effect on the magnetos or the operation of the engine. Oh, and you guessed it, they use a permanent magnet to generate the electrical field needed. This knowledge is vital for anyone interested in a pilot's license or even understanding the costs associated with getting a pilot license.

Lubrication

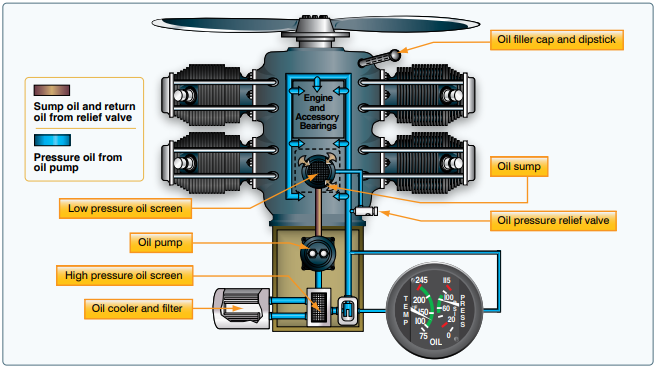

Lubrication is the blood of the engine. Without oil, the engine won’t take you very far, which is why it is so important to always check the engine oil and never fly below the manufacturer's recommendation. Here’s what the oil does for us:

Lubricates engine parts which also prevents corrosion

Cools the engine by reducing friction

Removes heat from the cylinder and disperses the heat evenly

Provides a seal between the cylinder walls and the pistons

Cleans contaminants that are later removed in oil changes

A common problem pilots face is faulty gauges, something emphasized in any quality aviation training. Let’s say that the engine temperature is in contact, as shown in the figure, but the oil pressure is reading 0 psi. We know that it is impossible for the engine to remain cool with no oil pressure, so we can assume that the gauge has failed and can plan a diversion to the nearest suitable airport to troubleshoot the problem. Now if we were to look at the engine gauges and the oil pressure is 0 psi and the oil temperature is rising, then a plan to land at the nearest airport should be made because a catastrophic engine failure is likely about to happen.

Vacuum Pump

The Vacuum pump is also engine-driven. It sucks filtered air from the cabin to run through vacuum instruments. If the engine is at low RPM, then there might not be enough vacuum suction to provide the gyros the energy they need to work properly. Since the vacuum pump is engine-driven, it has a shear coupling that may cause damage to the engine if it fails. Vacuum pumps are being phased out with the introduction of affordable digital, glass cockpit instruments, a key point covered in flight schools, especially at Aviator Zone Academy.

Alternator

The alternator is also engine-driven via a belt (that can be inspected in the front right of a Cessna cowling). The alternator can provide electrical current to the electrical system at different RPMs. Operating at low RPMs may cause a low voltage warning, which may be eliminated if/when RPMs increase. Failure of the belt or the alternator will result in the electrical system using only the battery as a source of energy. This should not be taken lightly in Instrument Meteorological Conditions (IMC) since all electrical power can fail, causing instruments to fail. However, on a VFR flight, this could just mean you won’t be able to communicate with Air Traffic Control (ATC) or operate the flaps, and gear (depending on the aircraft).

Starter

Pilots should be very grateful of this invention. Before we had starters, airplanes had to be started by hand, or also know as hand propping. Very dangerous, and tiring work if not done properly. Starters are only used for starting, you could possibly be flying with a failed starter and have no clue. Once the engine is turning you don’t need them anymore.

With that said it’s important to take care of the starter during starts. It is doing some hard work. Do no keep cranking and perform the cooling periods.

Most of our aircraft have Sky-tec Starters which have very high torque but can be easily burnt if not taken care of. Sky-tec requires pilots to not crank for more than 10 seconds, and then to allow a 20 seconds cooldown. You can repeat this up to 6 times, then after you must wait 30 minutes to allow the starter to cool down.

Carburetor

To overly simplify the carburetor, it mixes the fuel and air at the selected mixture ratio. The throttle cable is connected to the carburetor and controls the butterfly valve. The mixture is also connected to the carburetor and controls how much fuel is added to the air. Most light trainers will also have an accelerator pump. The accelerator pump can be visualized as a syringe that squirts gas into the venture, this aids in starting and during rapid acceleration to provide the engine with enough gas so it can respond.

Airplanes that have fuel injection do not use carburetors, although the systems are very similar. Carburetors are less fuel-efficient but are easier to start when the engines are hot. They are more susceptible to icing than fuel-injected engines and also require the use of carbheat during certain temperatures and high humidity.

.png?width=178&height=50&name=Aviator%20Zone%20Academy%20(5).png)

Submit a Comment